Inspection & Testing

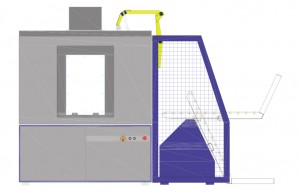

Tyre Testing System – Shearography tire test systems

The Shearography tire test systems have been developed for the non-destructive testing of new tires in R&D and quality control, as well as for the inspection of tire carcasses in the retreading industry. The technical basis of the systems is the phase shearography system.

During the test cycle, a pressure difference (vacuum, eg 50mbar) is generated in the vacuum chamber, thereby inducing deformations which are caused by the

expansion of the air pockets occurring in faulty areas in a tire carcass. With the phase shearography technique- a holographic measurement method which reliably detects material deformations in the range of microns- faulty areas can be localized clearly and reproducibly.

The tire test systems have successfully proven their functionality in the worldwide car, truck and aircraft industries, as well as in the Formula 1 racing tire business.

IR 125 NDT Tyre Nail Inspection Spreader

- Designed to detect pinholes, nail holes, cuts, cracks, porosity,etc

- Efficient & easy to operation

- Automatic tyre rotation stop when penetration detected with sparks

- Integral probes for light trucks & trucks

IR 125 Tyre Inspection Machine

For light truck & truck tyre

This machine spread and rotates the tyre at constant speed. A 40w light source provides clear and safe illumination.

- Handle tyre size from 640×14″ to 1300×24″

- Forward/Reverse rotation with 1hp/0.75 kw electric motor

- Constant and intermittent rotating speeds

- 40w lamp attached

- Tyre approach ramp

IR 325 Tyre Inspection Machine

For light truck, truck and wide-base single tyre

This machine spread and rotates the tyre at constant speed. A 40w light source provides clear and safe illumination.

- Handle tyres from 640×14″ to 1300×24″

- Including wide-base single tyres up to 455/55R 22.5

- 1HP / 0.75 Kw Electrical motor

- Forward / Reverse rotation

- Constant and intermittent rotating speeds

- 40w lamp attached

- Tyre approach ramp

Laser Marking System

The laser system creates distinct markings on a designated position of the tire sidewall. Tire makers and their OE customers can trace the individual product years after the date of manufacture.

Laser markings are more durable than barcode labels and more economical than RFID transponders.

Laser markings are machine-readable in the plant and human-readable once in the field.

- Maintenance free 30 W laser

- Marking field approx. 100 x 100 mm

- Engraving of 10 digits below 4 seconds

- Operation by touch panel

- Integrated filtration unit

- Class 1 laser system, CE mark

- Optional barcode reader

- Optional tire handling

- Open IT interface

- 110V/220V options

- Suitable for marking rubber, painted metals, plastics, wood

- Integrator versions available for customized manipulators

SCANNECT QR Code Laser Tyre Marking

For more product info, please click below link to access video playing:

Buffing Machine

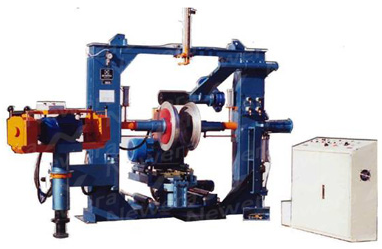

RAS 90-DC Computer Controlled Buffing Machine

- The programming of the computer and the method of operation of the RAS 90-DC are very simple and do not require any special preparation

- The computer will accept up to 1,000 programme to give any buffed profile for “hot” or “cold” retreading

- High productivity

- Low power consumption

- Suitable for tyres from 12″ to 24″ (including 18-22.5″) – minimum external tyre dismeter 515 mm., maximum 1250 mm

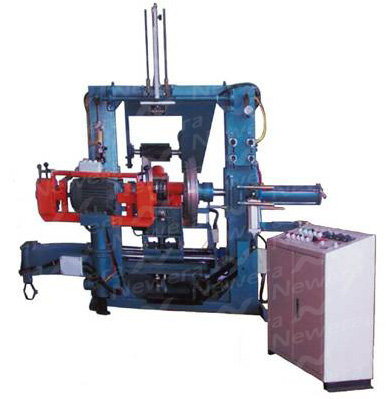

RAS 98-E Ultra Computer Controlled Buffing Machine

With expanding hub and rim assembly

Machine suitable for truck tyres up to 445 R 22.5″ and 495/45 R 22.5″

- 15″ colour touch screen user interface. The industrial PC provides two USB ports for data backup and software updating

- Buffing programme allows to control two crown buffing radii (Negative Radius is also possible)

- “BEC 90” steel belt detector and “Laser 300” computer interactive circumference measuring device

- Self diagnostic and troubleshooting system

- Articulated buffing/brushing arm, computerised sidewall brushing unit and cable lift are available on request

CR 50 Template Controlled Full/Top Cap Automatic (PLC)

Buffing Machine

The “PLC” controlled buffing machine is designed with template control for both full-cap & top-cap buffing of light truck & truck tyres. The built-in selections switch for three (3) type buffing mode are:

1. Manual: For peeling of used treads before actual buffing

2. Semi-auto: For tyre to be buffed multiple passes to archive the desire profile

3. Auto: For tyre to be buffed automatically according to be selected template profile at the shortest time

With the addition of the hand buffing/brushing unit, it can be used to find touch the shoulder to achieve better finishing.

- Main rasp motor: 25 Hp / 18 Kw

- Driving motor: 3 Hp / 2 Kw with selection of fast/slow speed

- Electricity: 415V / 3Ø / 50 Hz / 50 Amp

- Air supply: 8 bar

CR 30 Template Controlled Tyre Buffing Machine

Ideal for Precure Tyre Retreading on Light Truck & Truck Tyres

- Manual / Auto buffing mode to achieve desire tyre profile

- Addition of the hand rasp buffing / brushing assembly to fine touch on the shoulder for achieving better finishing

- Addition of steel belt detector for excellent quality control

- Main rasp motor: 20 Hp / 15 Kw

- Driving motor: 2.5 Hp / 1.8 Kw with selection of fast / slow speed

- Electricity: 415V / 3Ø / 50 Hz / 50 Amp

- Air supply: 8 bar

DCS 207 Dust Collection System

- Powerful air flow for efficient dust extraction from buffing rasp

- Eliminates heat and smoke from buffing, improves rasp-blade life

- Safer & cleaner working environment (better pollution control)

- Electric Motor: 7.5 Hp / 3,000 RPM

- Electricity: 415V / 3Ø / 50 Hz

Repair

IR 255 Tyre Repair Station

- Ideal for truck tyres repair or inspection

- Handles all passenger, light truck & truck tyres

- Built in lifter raises tyre to working height

- Optional tracks for monorail system

- Lifting capacity: 250 Kgs

- Lifting height: 750 mm

- Air supply: 8 – 10 bar

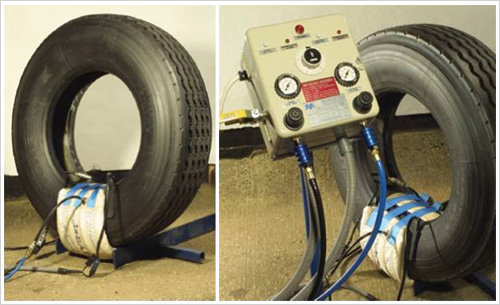

TRDD & TRRS Truck Tyre Repair

- For vulcanisation of repair in truck tire range from 8.25 to 1200×24 including low profile and super single 9.5-32 to 12.4-38 tractor

- First class distortion free repairs

- Even inside and out heat and pressure

- Patch and plug cured in one operation

- Even pressure over whole patch

- Differential air control

- The less expensive TRRS system provides all the above in radial repair but is limited to 7”x7” Patch size in repairs to cross ply

OTR Side Wall Repair

- For the repair of sidewall injuries in all OTR tyre in the range 1400×24 to 29.5-29 including skidder and terra tyre

- Easy to operate, with total assembly on the tyre taking under 3 minutes

- Provides even inside and outside tyre heat and pressure

- Vulcanises the patch and plug in one operation; saving time and increasing workshop through put

- Repairable injury size can be extended by vulcanizing plug only and using a chemical patch

B&J Buffing Kit Basic

B&J Buffing Kit Pro

Cementing

3 x 50LT Airless Spray Tank

This tank is complete with stirrer, air filter / regulator / oiler, air blower gun, high pressure air pump and airless spray gun.

- Driving motor: 0.25 Hp / 0.18 Kw

- Electricity: 415V / 3Ø / 50 Hz / 3 Amp

- Air supply: 8 bar

150 LV Vertical Solution Mixer

This machine is designed for making your own rubber solution or cement by mixing cushion gum and rubber solvent.

- Capacity of tank: 150 Liters

- Driving motor: 1 Hp / 0.75 Kw

- Electricity: 415V / 3Ø / 50 Hz / 5 Amp

Building

AZ Retrax Extruder Machine

Cushion Gum Extruder for precured treads

- Computer controlled / Simple / Robust / Effective

- Save cushion gum costs by using single size of feed strip

- Save cement spraying costs with correctly formulated cushion gum

- Save labor costs by automatic skive filling

- Optional Item: Stitching Unit

BR 328J Tyre Building Machine

Motorized stitcher assembly provides better adhesion

- Suitable for procured process & camelback

- Applicable for light truck & truck tyres size from 15” to 12.00 – 24”

- Dual selection of stitching pressure for cushion gum, liner & camelback

- Rotation motor: 2 Hp / 1.5 Kw with selection of fast/slow speed

- Stitcher motor: 2 Hp / 1.5 Kw with selection of fast/slow speed

- Voltage: 415 / 3 / 50

- Total amperage: 10 Amp (approx)

- Air supply: 8 bar

BR 330 Tread Building / Stretching Machine

For precure liner

- Two speeds motorized stitching assembly provides extra power

- Uniform tread stretching for perfectly pattern matching

- Fast/Slow speed chain-drive motor and High/Low stitching pressure improve productivity and retread quality

- Driving motor: 1.8 Hp / 1.3 Kw with brake & selection of fast/slow speed

- Electricity: 415V / 3Ø / 50 Hz / Amp

- Air supply: 8 bar

Enveloping

ER 815 OTR Envelope Spreader

- Convenient installation & removal of outer envelope

- Applicable for tyres size from 14.00 – 24” to 2400 R35

- Motor power: 2 Hp / 1.5 Kw

- Voltage: 415 / 3 / 50

- Total amperage: 5 Amp (approx)

- Air supply: 8 bar

ER 215 Envelope Spreader

For precure tyre retreading

- Stronger jaws to carry out spreading work

- Spreads the envelope, puts in or lifts out the tyre

- Labour saving, requires only one operator

- Pneumatic powered

- Suitable for all light truck and truck tyres with 16″, 20″, 22.5″ & 24″ beads

- Comes complete with heavy duty tyre lifter

- Maximum tyre size: 1200 R24

- Working pressure: 8 bar

- Tyre lift capacity: 150 Kgs

ER 118 Rim Mounting Station

This machine is designed to mount the pressure curing rim onto the tyre or to remove from it

- Tilting table handles the truck tyres easily

- Designed to handle all 20″ and 22.5″ precure rims. Others rim sizes may be specified.

- Air operated

- Pressure required: 8 bar

ER 160 Twin Tilting Table

A useful piece of equipment in the precure tyre retreading process

- For inserting and removing of inner envelopes

- For inserting and removing of locking rings

- Suitable for all radial truck tyres operation

Curing

Ferlex Chamber

Ferlex is continuously working to supply the market with top premium quality products. For this reason, its policy is focused on the production growth and improvement.

The experience in producing over two thousand autoclaves for a number of different purposes is certified by the satisfaction and loyalty of our clients. At least, this is the result of over 30 years of continued work and learning.

Ferlex manufactures autoclaves from light truck to OTR tyre and ranging from 6-tyre to 30-tyre.

With safety, quality and breakthrough technology, Ferlex autoclaves provide your production line with high output and uniformity. They may be manufactured at a number of different sizes and configurations, according to the characteristics of the facilities and production volumes of the customer.

- Radial Locking Door: Easy, fast and light opening and closing movement requiring no levers, pistons, or other maintenance generating mechanisms. The radial system avoids friction with the trim, and decreases wear

- Encapsulated Motor: Since the motor is installed encapsulated externally, it is operating in lower temperature but working at the same pressure; the motor needs no mechanical seal, motor pulley and fan belts, thus the autoclave fan are running more efficiently and less maintenance cost

- Internal Thermal Insulation: As the device body requires no heating, its operating time is shorter, and the process faster, thus increasing the output, and enabling great power or steam economy

- Electric Control Board: Set up with high quality components, it provides higher reliability and easy replacement. The electric control board further provides accurate control of the vulcanization greatness, thus securing repeatability of the conditions in all working cycles

- Kit EPS (Third Pressure): Introduces a positive pressure into the tread design, thereby causing it to be set over the casing more firmly. Increases the envelope life time, distributes the connection evenly, and prevents connection deformation

- Double Heating (Optional): The autoclave may be supplied with double heating means, and work either with electric resistances or steam heat exchanger

Final Inspection

NE 210 High Pressure Testing

- Handles tyres from 15″ to 22.5″

- Tyre inflation pre-set at 2, 4 & 8 bar (max) for a better QC inspection

- Enclosed by steel cage as safety protection

- Testing cycle ended automatically to reduce supervision work

- Well lighted within the cage for better visual inspection

- Driving motor: 2Hp / 1.5 Kw with programmable fast/slow speed

- Electricity: 110V / 3Ø / 60 Hz / 40 Amp

- Air supply: 10 bar